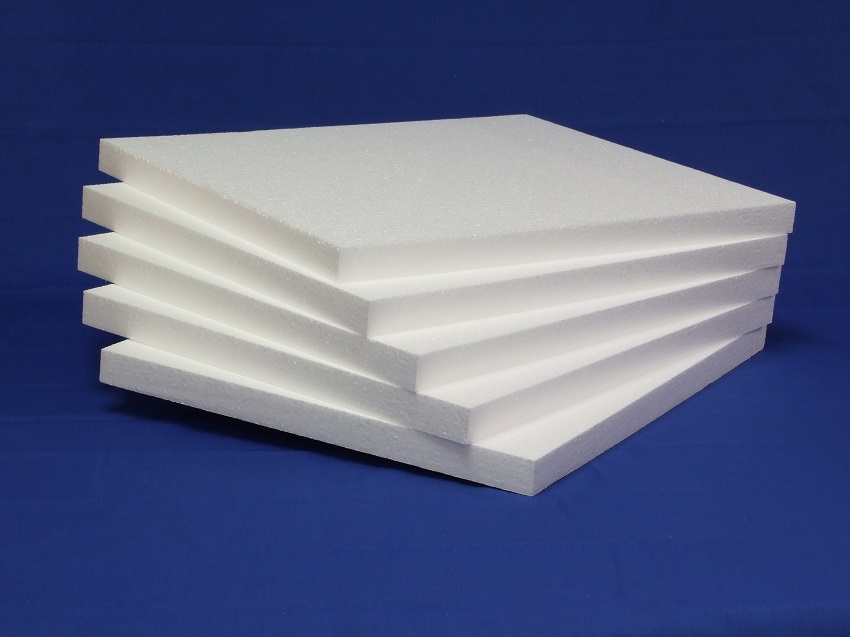

Are you seeking an effective, eco-friendly insulation solution for your construction projects? Look no further than expanded polystyrene (EPS). With its excellent thermal insulation properties and versatility, EPS has become popular in the construction industry. In this article, we will explore the benefits of using expanded polystyrene in construction and how it can contribute to energy efficiency and sustainability. Let’s delve into the world of expanded polystyrene in construction and discover why it has gained widespread recognition.

The Advantages of EPS in Construction

Superior Thermal Insulation

One of the primary reasons for the popularity of EPS in construction is its exceptional thermal insulation capabilities. EPS has a high R-value, which measures its resistance to heat flow. Its closed-cell structure minimizes heat transfer, making it an efficient choice for keeping buildings cool and warm in cold climates. By reducing the reliance on heating and cooling systems, EPS insulation helps conserve energy and reduce utility costs.

Lightweight and Easy to Handle

EPS insulation is incredibly lightweight, making it easy to transport and install. Unlike other traditional insulation materials, EPS does not add significant weight to the building structure. Its lightweight nature also simplifies handling during construction, allowing for quicker and more efficient installation.

Moisture Resistance

Moisture can cause significant damage to buildings if not properly managed. EPS insulation is inherently resistant to moisture, making it an ideal choice for areas prone to high humidity or frequent water exposure. The closed-cell structure of EPS prevents water absorption, maintaining its thermal and structural integrity over time.

Excellent Structural Properties

In addition to its insulation properties, EPS also offers excellent structural support. It can be used as a load-bearing material, providing strength and stability to construction projects. EPS blocks and panels have high compressive strength, making them suitable for various applications, including foundations, walls, and roofs.

Energy Efficiency and Sustainability

EPS insulation plays a significant role in improving the energy efficiency of buildings. Minimizing heat transfer reduces the need for excessive heating and cooling, resulting in lower energy consumption and reduced carbon emissions. Additionally, EPS is a sustainable insulation choice. It can be recycled and has a low environmental impact during manufacturing.

Noise Reduction

Apart from thermal insulation, EPS also provides effective noise reduction. Its cellular structure acts as a sound barrier, minimizing the transmission of external noises into the building and vice versa. This feature is particularly beneficial for residential, commercial, and industrial structures located in noisy environments or near busy roads.

Now that we have explored the advantages of using EPS in construction, let’s delve into its various applications.

Applications of EPS in Construction

EPS insulation offers a wide range of applications in construction projects. Let’s explore some of the most common uses:

Insulation Panels and Sheets

EPS panels and sheets are widely used for insulating walls, roofs, and floors. They are available in various thicknesses and sizes, providing flexibility to suit different construction requirements. These panels are easy to install and offer excellent thermal performance.

Insulation Boards and Blocks

EPS insulation boards and blocks are commonly used in both residential and commercial construction. They are lightweight, durable, and can be easily cut to fit specific dimensions. EPS boards and blocks are ideal for insulating foundations, exterior walls, and ceilings.

Roof Insulation

EPS insulation is highly effective for insulating roofs. It can be used in both flat and pitched roofs to prevent heat loss or gain. EPS roof insulation not only enhances energy efficiency but also helps improve the overall durability and lifespan of the roof.

Wall Insulation

EPS insulation is widely used in wall construction for its thermal and moisture resistance properties. It can be incorporated into cavity walls or installed as external insulation systems. EPS wall insulation helps maintain a comfortable indoor environment while reducing energy consumption.

Floor Insulation

EPS insulation is also suitable for insulating floors, providing thermal comfort and energy efficiency. It can be used in concrete slabs, suspended floors, or timber floors. EPS floor insulation minimizes heat loss through the floor and improves the overall thermal performance of the building.

Insulated Concrete Forms (ICFs)

Insulated Concrete Forms (ICFs) are gaining popularity in construction, and EPS plays a crucial role in their construction. ICFs are used for building walls and foundations, combining the strength of concrete with the insulation properties of EPS. These forms offer exceptional energy efficiency, structural integrity, and sound insulation.

By utilizing EPS insulation in these various applications, construction projects can achieve superior energy efficiency, durability, and occupant comfort.

In the next section, we will compare EPS insulation with other commonly used insulation materials to highlight its advantages.

EPS vs. Other Insulation Materials

When considering insulation options for construction projects, it’s essential to understand the differences between EPS and other insulation materials. Let’s explore a few notable comparisons:

Foam Board Insulation

Foam board insulation, including EPS, is known for its excellent thermal resistance. However, EPS offers distinct advantages such as its lightweight nature, ease of installation, and affordability compared to other foam board insulation options.

Rigid Foam Insulation

Rigid foam insulation, like EPS, provides superior thermal performance. However, EPS stands out with its moisture resistance, recyclability, and low environmental impact.

Extruded Polystyrene (XPS)

Extruded polystyrene (XPS) is another type of foam insulation material. While XPS offers similar insulation properties to EPS, it is generally more expensive and has a higher environmental impact due to its manufacturing process. EPS is often a more cost-effective and sustainable choice.

By choosing EPS insulation, construction professionals can benefit from its unique properties while ensuring energy efficiency and sustainability. To gain a better understanding, let’s explore some real-life examples of EPS usage in construction.

Case Studies: Real-Life Examples of EPS in Construction

Residential Buildings

In residential construction, EPS insulation has been extensively used in various applications. It provides efficient thermal insulation for walls, roofs, and floors, resulting in energy savings and enhanced comfort. Homeowners can enjoy a well-insulated living space that reduces heating and cooling costs.

Commercial Buildings

EPS insulation has also found widespread use in commercial buildings. From retail spaces to office complexes, EPS is utilized in wall systems, roof insulation, and insulating concrete forms. Its versatility, lightweight nature, and energy-saving properties make it a preferred choice for commercial construction projects.

Industrial Structures

Industrial structures, such as warehouses and factories, often require effective insulation to maintain optimal temperature and reduce energy consumption. EPS insulation panels and sheets provide a cost-effective solution, ensuring a well-insulated and energy-efficient environment for industrial operations.

These case studies demonstrate the practical application and positive outcomes of incorporating EPS insulation in construction projects. Moreover, EPS insulation offers several environmental benefits, which we will discuss in the next section.

Environmental Impact of EPS

Green Insulation

As sustainability becomes a significant consideration in construction, EPS insulation stands out as a green insulation option. It contributes to energy efficiency, reduces carbon footprint, and helps minimize the environmental impact of buildings. By using EPS insulation, construction professionals and homeowners can make environmentally conscious choices.

Sustainable Manufacturing Process

The manufacturing process of EPS insulation involves minimal environmental impact. The use of steam to expand polystyrene beads and the ability to recycle EPS waste contribute to its sustainability. EPS insulation manufacturers often employ advanced recycling systems to reduce waste and promote a circular economy.

Recyclability and Waste Reduction

EPS insulation is highly recyclable. Post-consumer EPS waste can be collected, compacted, and transformed into new EPS products. This recycling process significantly reduces the amount of EPS waste that ends up in landfills, making EPS insulation an eco-friendly choice for construction projects.

By choosing EPS insulation, construction professionals can actively contribute to sustainable and eco-friendly construction practices.

In the next section, we will explore important factors to consider when selecting EPS insulation products for specific applications.

Choosing the Right EPS Products

When selecting EPS insulation for construction projects, several factors need to be considered. Let’s discuss some essential considerations:

Understanding R-Value

R-Value measures the thermal resistance of insulation materials. Different construction projects require different R-Values based on climate and building codes. Understanding the required R-Value helps in selecting the appropriate EPS insulation products for optimal energy efficiency.

Certifications and Standards

Look for EPS insulation products that meet industry certifications and standards. These certifications ensure that the insulation meets specific performance criteria, fire resistance requirements, and environmental standards.

Considerations for Specific Applications

Each construction application may have specific requirements. For example, selecting EPS insulation for a roof might involve considering factors such as waterproofing, compatibility with roofing materials, and fire resistance. Understanding the specific application requirements ensures that the chosen EPS insulation product delivers the desired performance.

By carefully considering these factors, construction professionals can choose the right EPS insulation products for their specific project needs.

In the next section, we will discuss the installation and maintenance aspects of EPS insulation.

Installation and Maintenance of EPS Insulation

Proper Installation Techniques

Proper installation is crucial for the optimal performance of EPS insulation. Following manufacturer guidelines and employing trained professionals ensure correct installation. Adequate insulation thickness, tight joints, and proper sealing are key aspects to consider during installation.

Common Maintenance Practices

EPS insulation requires minimal maintenance. Regular inspection for any damage, moisture infiltration, or signs of degradation is recommended. Addressing any issues promptly helps maintain the insulation’s effectiveness and prolong its lifespan.

By adhering to proper installation and maintenance practices, construction projects can maximize the benefits of EPS insulation.

Now, let’s address some common questions related to EPS insulation in the FAQs section.

FAQs (Frequently Asked Questions)

Can EPS be used in extreme weather conditions?

Yes, EPS insulation performs well in extreme weather conditions. Its closed-cell structure and thermal resistance make it suitable for both hot and cold climates.

Is EPS suitable for soundproofing applications?

While EPS provides some level of sound insulation due to its cellular structure, for specific soundproofing requirements, additional measures like acoustic barriers or specialized insulation materials may be necessary.

How long does EPS insulation last?

With proper installation and maintenance, EPS insulation can last for the lifetime of a building. It is a durable material that retains its thermal and structural properties over time.

Can EPS contribute to LEED certification?

Yes, EPS insulation can contribute to LEED (Leadership in Energy and Environmental Design) certification. Its energy-efficient properties, recyclability, and sustainable manufacturing process align with the goals of LEED-certified projects.

What is the cost of EPS insulation compared to other materials?

EPS insulation is a cost-effective choice compared to many other insulation materials. Its affordability, combined with its energy-saving benefits, makes it a desirable option for construction projects.

Conclusion

Expanded polystyrene (EPS) insulation offers various benefits for construction projects. Its superior thermal insulation properties, lightweight nature, moisture resistance, and structural support make it versatile. By incorporating expanded polystyrene in construction, construction professionals can enhance energy efficiency, reduce carbon footprint, and create comfortable living and working spaces.